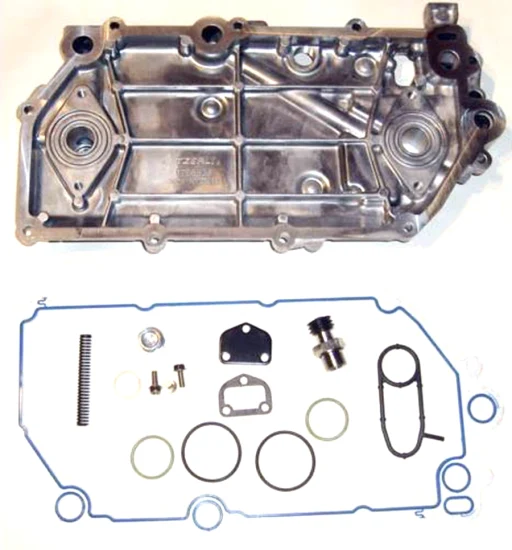

Factory Manufacturing Titanium Gasketed Plate Type Heat Exchanger for Marine Seawater Engine

Product Description Plate heat exchanger is an ideal equipment for heat exchange between liquid and steam. The utility m

Basic Info

| After-sales Service | Online Technical Service |

| Warranty | 12 Months |

| Customized | Customized |

| Performance | Pressure Resistant, Temperature Resistant, High Heat Transfer Efficiency |

| Brand | Wintech |

| Certification | ISO, ASME |

| Style | Plate |

| Design Temperature | 350 Degree |

| Design Pressure | 3.2MPa |

| Design Standards | ASME / Nb/T47004 |

| Heat Transfer Surface | Plate |

| Core | Corrugated Plate |

| Plate Material | SS304, 316, Ti |

| Frame Material | Carbon Steel |

| Lead Time | 30 Days |

| Application Field | Petrochemical, Chemical, Edible Oil, Sugar Plant |

| Loading Port | Qingdao Port |

| Plate Type | Wide Straight Channel |

| Features | High Heat Transfer Efficiency |

| Installation | Vertical or Horizontal |

| Transport Package | Wooden Case |

| Specification | Customized |

| Trademark | Wintech |

| Origin | Shandong China |

| HS Code | 8419500090 |

| Production Capacity | 800 Sets/Year |

Product Description

Product Description

| Product Name: | Welded Plate Heat EXchanger | Certification: | ISO/ASME |

| Working Pressure: | Max.3.2 MPa | Plate Material: | SS304/SS316/254SMO/Ti |

| Working Temperature: | Max.350°C | Frame Material: | Carbon Steel |

| Plate Thickness: | 0.8~2.0mm | Delivery Time: | 90 Days |

Plate heat exchanger is an ideal equipment for heat exchange between liquid and steam. The utility model has the advantages ofhigh heat exchange efficiency, small heat loss, compact and light structure, small floor area, wide application, long servicelife, etc. Under the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tube heat exchanger,the floor area is one third of the tube heat exchanger, and the heat recovery rate can be as high as 90%.

Main Features☆ Plate pack is fully welded without gaskets;☆ The frame can be disassembled for repairing and cleaning;☆ Compact structure and small footprint;☆ High heat transfer efficient;☆ Can be installed either vertically or horizontally.☆ Short flow path fit low-pressure condensing duty and allow very low pressure drop.☆ A variety of flow form meets all kinds of complex heat transfer process.

Company Profile

About us

Incorporated in 2012, Shandong Wintech Technology has evolved to be a technology driven heat exchanger manufacturer. So far we have got ISO9001 and ASME certificates.We have more than 200 staffs, including 30 technical engineers. The factory covers an area of 670,000 square meters and has construction area more than 30,000 square meters. Production capacity is 8000 tons per year. The company has been awarded as heat transfer technology center and engineering laboratory of Zibo city.

Products Exhibition

Why Choose Us

We set up all art state of facilities on processing from the uncoiling steel machine, hydraulic oil pressing machine, Gantry milling, resistance welding machine, welding robot, Laser welding machine,testing from complete instruments in our lab, make every set of equipment is dispatched at the qualified controlling. Basing on our powerful product capability, many certification and awards are achieved. ISO14000, ISO9000, OHSAS18001, CNAS, IAF, ASME make us prodce and supply equipment as per the ASME standard complying with international market consumption, now our clients are from Russia, Uzbekistan, Thailand, South America, India,Indonesia, Malaysia,Iran, Saudi Arabia, Argentina, and other countries and areas.

After-sales Service: 1. One-year free warranty and life-long maintenance service 2. Equipment o peration and maintenance vedio guide for the c ustomers 3 . Help to do worker training 4 . On-line support every day FAQ:1.

Q:Are you a factory or trading company?

A:We are one of the largest heat exchanger manufactory and factory.2

Q:Can we visit your factory before placing orders?

A: Sure, warmly welcome to our factory! 3

Q:What ' s the in fo needed if I send one inquiry ? A : Pls tell us the working conditions, mediums,t emperature ,pressure, equipment ' s m ateria l,size,quantity, and other special requests 4

Q:What is the MOQ?

A:We accept loose quantity order,any trial orders or mixed order 5

Q:How does your factory do quality control?

A:Quality is priority ,we make relevant strict testing before delivery Our factory has already obtained ISO9001 quality and ISO 14001 AESE certificateEnvironmental management system certificate.

Send to us