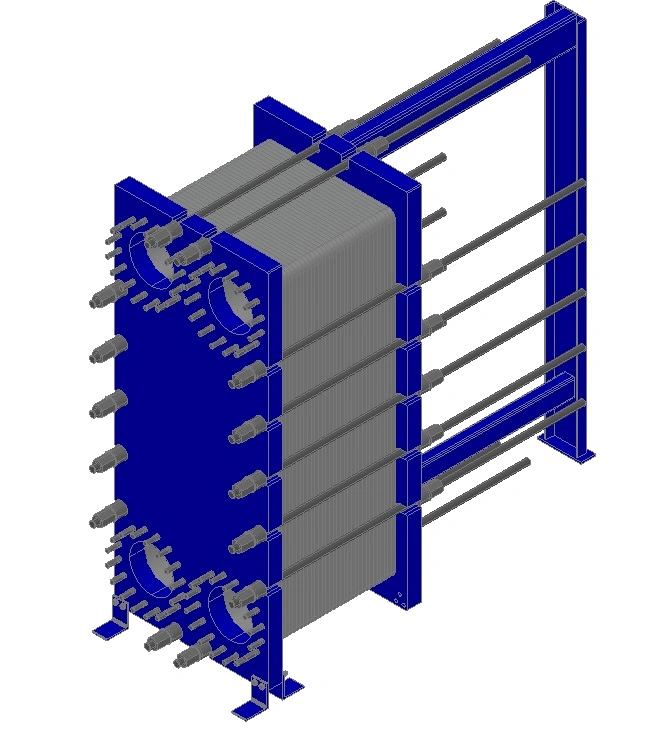

Paper & Pulp Industry Wide Gap/Free Flow Plate Heat Exchanger

Heat Exchanger Plate Heat Exchanger for Paper & Pulp Industr Products Description Free flow plate heat exchanger, specia

Basic Info

| Model NO. | Heat Exchanger |

| Gasket Material | NBR,EPDM,HNBR,Viton,Viton G,Neoprene |

| Frame Material | Stainless Steel,Carbon Steel,Coated Stainless Stee |

| Delivery Time | Within 5-30 Working Days (Depending on The Qty) |

| Transport Package | Standard Export Plywood Case & Customizing |

| Specification | CE, SGS, ISO14001, |

| Trademark | Diguang |

| Origin | Shanghai |

| HS Code | 8419500050 |

| Production Capacity | 5000 Sets/Year |

Product Description

Heat Exchanger Plate Heat Exchanger for Paper & Pulp IndustrProducts Description

Free flow plate heat exchanger, special free fluid design can effectively treat the fluid of higher viscosity,

larger particles, up to 11mm constant gap. It is no metal contact, can avoid dead spots,prevent blockage.

It has excellent heat transfer performance, easy disassembly, cleaning, maintenance, so it apply for sugar,

paper,fiber,Fermentation, crystallization, plastic,printing&dyeing and other process.

Advantages

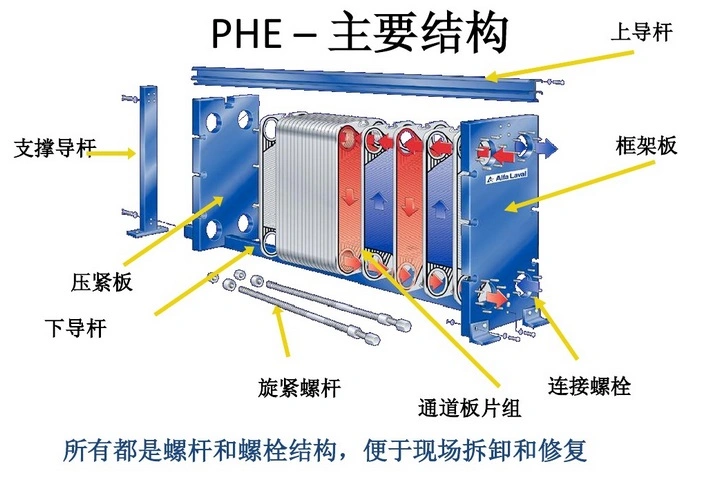

1.Precision heat transfer: closer approach temperature, true counter current flow, 80-90% less hold-up volume.

2.Low overall cost: low capital investment, reduced installation costs, limited maintenance and operating costs.

3.Maximum reliability: less fouling, stress, wear and corrosion.

4.Environmentally responsible: minimum energy consumption for maximum process effect, reduced cleaning.

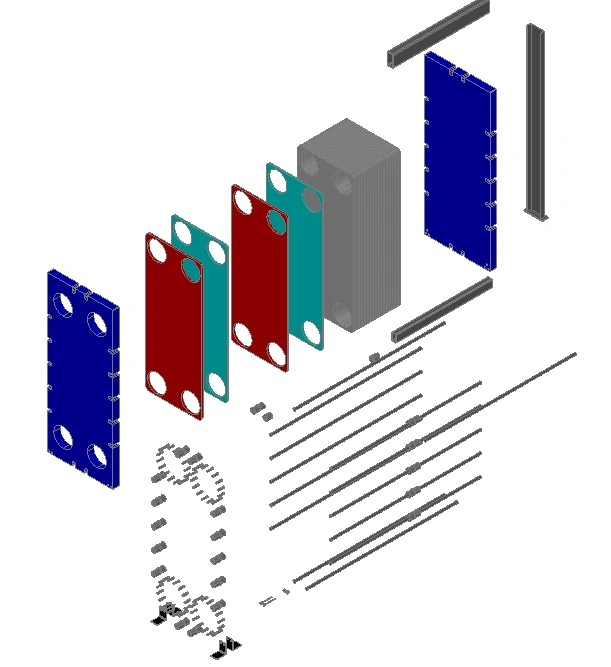

5.Easy to expand capacity: simply add or remove plates on the existing frame.

| Plate and frame heat exchanger Specifications | ||||||||

| Model | Frame Type | Dimensions(mm) | Connections (mm) | Max Flow (M3/H) | ||||

| 1.0Mpa | 1.6MPa | 2.5MPa | Height | Width | Length | |||

| TF3SM | LF10 | LF16 | - | 320 | 160 | 140-440 | 20-30 | 20 |

| TF3 | LF10 | LF16 | - | 480 | 180 | 250-400 | 20-30 | 20 |

| MF10 | MF16 | - | 480 | 180 | 250-500 | 20-30 | 20 | |

| TF6B | LF10 | LF16 | LF25 | 920 | 320 | 500-700 | 50-60 | 40 |

| MF10 | MF16 | MF25 | 920 | 320 | 500-1400 | 50-60 | 40 | |

| TF6M | LF10 | LF16 | LF25 | 920 | 320 | 500-700 | 50-60 | 40 |

| MF10 | MF16 | MF25 | 920 | 320 | 500-1400 | 50-60 | 40 | |

| TF10B | MF10 | MF16 | MF25 | 1100 | 470 | 700-2300 | 100 | 190 |

| TF10M | MF10 | MF16 | MF25 | 1100 | 470 | 700-2300 | 100 | 190 |

| TF15B | HF10 | HF16 | HF25 | 1885 | 650 | 1100-3700 | 150 | 400 |

| TF15M | HF10 | HF16 | HF25 | 1885 | 650 | 1100-3700 | 150 | 400 |

| TF20M | HF10 | HF16 | HF25 | 2140 | 780 | 900-4100 | 200 | 600 |

| TF25B | HF10 | HF16 | HF25 | 2590 | 920 | 1600-3500 | 250 | 1100 |

| TF30 | HF10 | HF16 | HF25 | 2880 | 1170 | 1600-4800 | 300 | 1300 |

| TF10FF | MF10 | - | - | 1650 | 520 | 900-3500 | 100 | 190 |

| TF20FF | HF10 | - | - | 2100 | 750 | 3600-4100 | 200 | 600 |

Application

Shanghai Empire plate heat exchangers are widely used in multiple industries and applications.We

provide specified service for various requirements.Our plate heat exchangers are qualified to be applied for following industries.

1.Refrigeration: used for condenser & evaporator

2.HVAC: intermediate heat exchanger cooperated with the boiler, high-rise building intermediate heat exhcangers.

3.Chemical Industry: soda ash industry,tynthetic ammonia,alcohol fermentation,resin composite cooling,etc.

4.Food & Beverage: juice sterilization cooling,animal and plant oil heating and cooling.

5.Central Heating: thermal power plant waste heat district heating,bath water heating.

6.Paper Industry: bleaching process heat recovery,wash slurry heating.

7.Power Industry: high voltage transformer oil cooing,generator bearing oil cooling,etc.

8.Metallurgical Industry: aluminate liquor heating and cooling,steel-making process cooling,etc.

9.Mechinery Industry: all kinds of quenching liquid cooling,reduser lubricating oil cooling,etc.

10.Marine: shipbuilding.

11.Medical Industry: medicine making.

Send to us